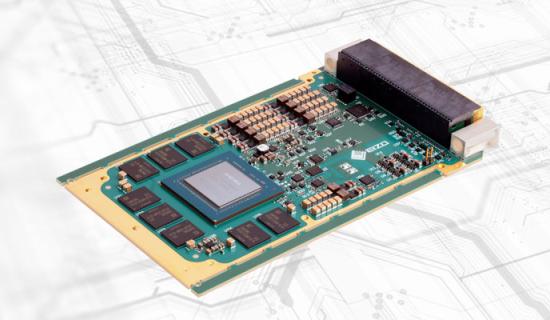

OpenVPX 3U and 6U. VME. 3U and 6U CompactPCI. Intel or Power Architecture. Whatever’s right for your program – and backed by our long term support and technology insertion programs to maximize return on investment.

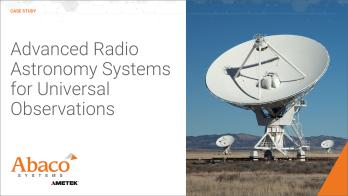

Abaco has an extensive track record in helping our customers turn sensor-acquired data into actionable information in the shortest time and at the lowest bandwidth in a broad range of digital and analog applications.

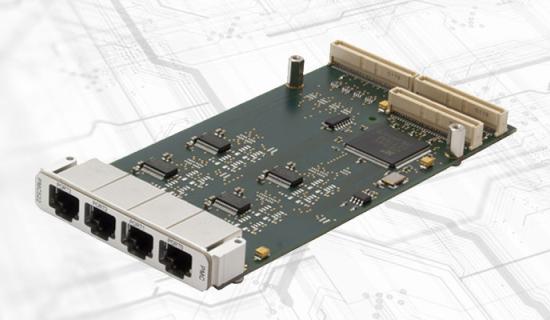

Abaco’s unique OpenWare switch management software provides an extensive, powerful and flexible feature set that, together with our 30+ years of experience, means we can solve our customers’ toughest networking problems.

Leading edge commercial technology coupled with Abaco’s ruggedization expertise delivers blazing graphics and video performance from a range of platforms and small, lightweight mission-ready, pre-integrated subsystems.

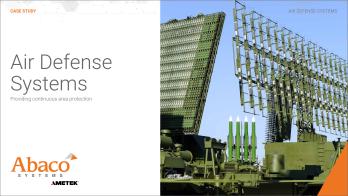

Powerful, flexible and based on open standards, Abaco’s Mission Ready Systems are pre-integrated and pre-qualified so that they’re ready for immediate deployment – minimizing cost, risk and program leadtime.

With the addition of the innovative MMS line of “create it yourself” I/O products, your ability to configure exactly the right connectivity options to create a complete system has never been greater – or more flexible.

Our broad and deep line of avionics interfaces, test platforms, tools and software support the development of modern military and commercial aircraft from small SWaP-constrained platforms to commercial airliners

AXIS enables simpler and faster development of sophisticated, high performance applications, helping you reduce risk and cost and minimize time-to-deployment.