Share

HUNTSVILLE, Ala.— June 11, 2020 Abaco Systems today announced first customer shipments of the GBX25 6U VME managed Ethernet switch, which is being manufactured at the Towcester, UK facility using state of the art component placement systems that have recently been installed.

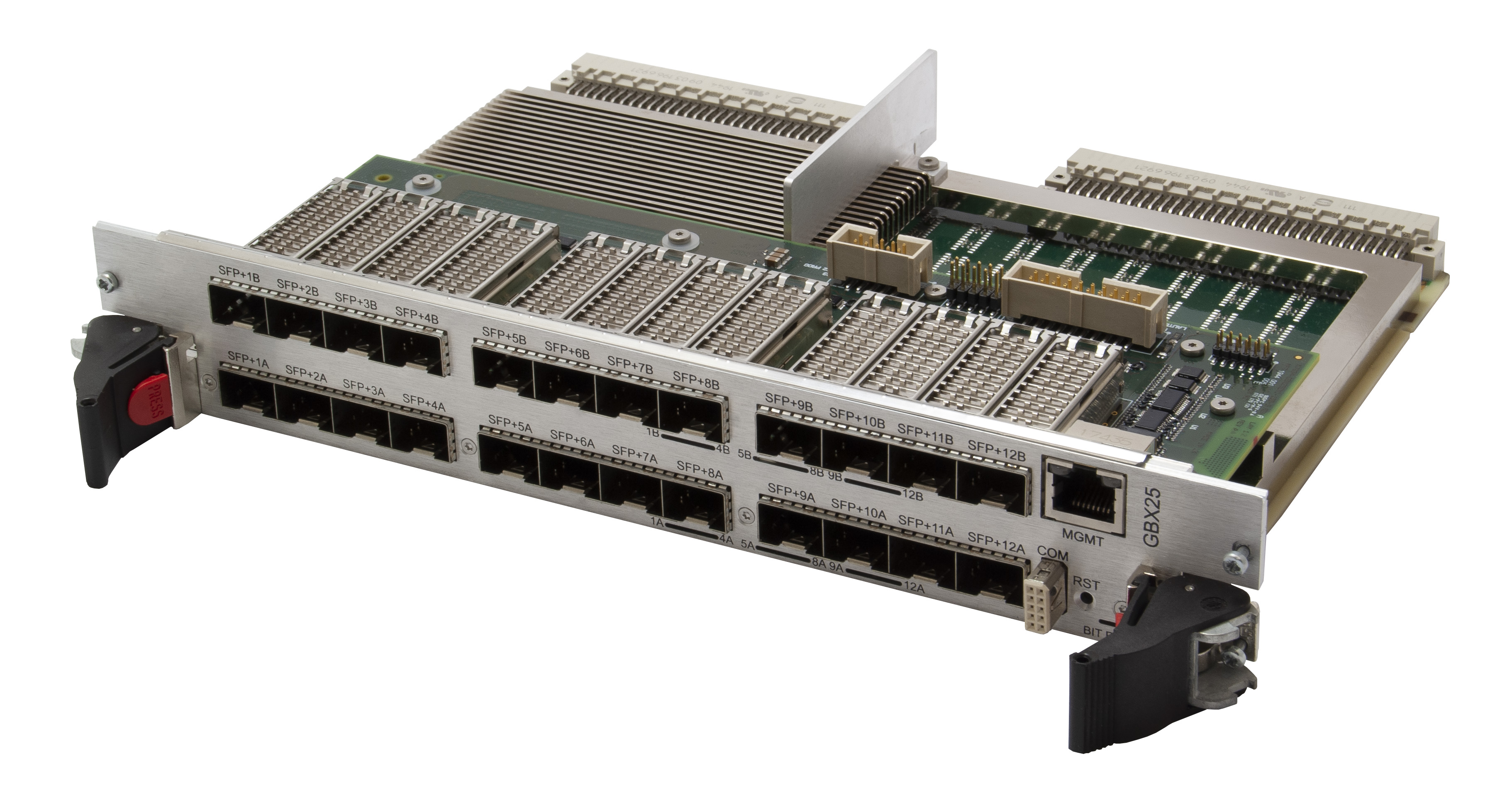

The GBX25 enables users to free up slot space as well as valuable power and cooling resources in existing chassis by using a single switch to replace multiple switch cards while maintaining the range of communication protocols—including 100-FX—and cable types typically installed in legacy systems. It is available with up to 40 ports (combination of front and rear) that support a variety of copper and fiber cable types. The GBX25’s use of standard SMP modules for a variety of basebands including 100-FX, 1000-SX/LX/T, and 10G-SR/LR enables users to combine multiple communications capabilities on a single card, reducing slot occupancy compared with previous multi-card architectures.

The GBX25 is 100% pin-compatible with the GBX24 and RM921, but has been upgraded with Abaco’s OpenWare switch management software. OpenWare was created by Abaco at its Networking Innovation Center, and numerous customers have benefited significantly from access to the development team’s expertise to smooth transition or to develop application-specific functionality, providing more rapid deployment or a custom networking solution.

Abaco can provide users with access to the OpenWare development team for transition support and advanced function support for existing or new applications.

The first GBX25 units bound for customers are being produced on Abaco's new line of ASM SX surface-mount placement machines. The Towcester plant recently invested in four of these units that can place components from 0.0625 mm2 to 22,000 mm2 at a rate of up to 100,000 components per hour. The on-the-fly reconfiguration and multi-head versatility of the ASM SX gives flexibility, speed and precision that reduces cycle time and cost and improves first pass yield. New technologies allow for reduced soldering, further improving key performance metrics.

Steve Leeds, Programming Engineer at Abaco Systems in Towcester, said: “The complete suite of new features and tools enables us to produce new products with world class performance and a significant increase in first pass yield and commensurate drop in rework.”

Alex Baldock, Vice President of Operations, Abaco Systems in the UK, said: “Our investment in equipment for the Towcester facility demonstrates Abaco’s commitment to making an important contribution to our customers’ success by delivering the best products and technologies on time and on budget. Innovative products like the GBX25 can only be brought to market through equally innovative manufacturing.”

About Abaco Systems

With more than 30 years’ experience, Abaco Systems is a global leader in open architecture computing and electronic systems for aerospace, defense and industrial applications. We create innovative, modular solutions based on open standards that are characterized by outstanding price/performance, ultimate rugged reliability and minimal SWaP. Our goal is to be a significant contributor to our customers’ success, partnering with them to reduce cost, time-to-deployment and risk and supporting them over the long term. With an active presence in hundreds of national asset platforms on land, sea and in the air, Abaco Systems is trusted where it matters most. www.abaco.com

For more information, contact:

Alisa Coffey

Head of Marketing

Abaco Systems, Inc.

All trademarks are the property of their respective owners.